Ceolus™ UF

Ceolus™ UF is a porous MCC with balance of compactibility and flowability.

It enables a balance of tablet hardness and tablet disintegration. It solves tableting issues such as insufficient API

content uniformity or over-lubrication.

Functional benefits

- Enables a balance of tablet hardness and tablet disintegration

- Solves tableting issues (Insufficient API content uniformity, over-lubrication)

- Enables poorly flowable and/or low dose formulations

- Enables high speed tableting

Function & features

- Balance of compactibility and flowability

- High swellability

- Low sensitivity to lubricant

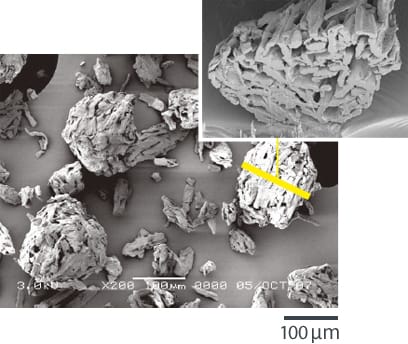

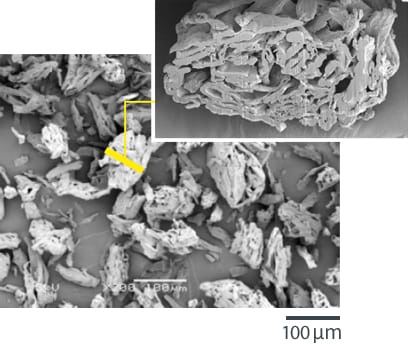

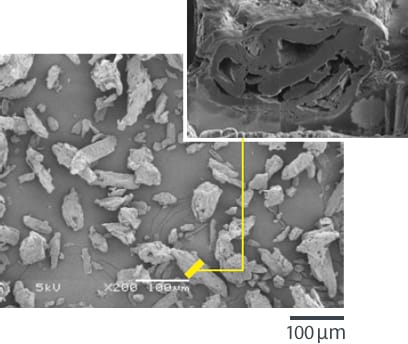

- Porous particles

Map of Ceolus™ Compactibility vs. Flowability

* Comparison of tablet hardness, with the formulation of PH-101 = 1 set as the index point

Formulation: Acetaminophen/MCC = 70/30

Experimental

example

Tablet hardness

Tablet weight variance

Ascorbic acid/MCC/Spray dried lactose/CCS/Mg-St=75/20/3/2/1.5 (extra) (%),

Direct compression (Rotary press), Tablet size: 180 mg, φ8 mm -12 R

Grade lineup

UF-702

UF-711

Subject of comparison

PH-101

General properties

| Grade | Average Particle Size(μm) |

Bulk density (g/cm3) | Repose Angle(°) | Loss on Drying(%) |

Water absorption (%) |

Oil absorption (%) |

|

|---|---|---|---|---|---|---|---|

| Ceolus™ UF Porous MCC with balance of compactibility and flowability |

UF-702 | 90 | 0.29 | 34 | 2.0-6.0 | 240 | 160 |

| UF-711 | 50 | 0.22 | 42 | 2.0-6.0 | 240 | 150 | |

| Ceolus™ PH Standard grade with high quality |

PH-101 | 50 | 0.29 | 45 | 2.0-6.0 | 200 | 120 |

| PH-102 | 90 | 0.30 | 42 | 2.0-6.0 | 200 | 140 |

All values presented here are solely for the purpose of basic reference and should not be regarded as specifications.

Pharmacopoeia listings

JP : Microcrystalline Cellulose

USP/NF : Microcrystalline Cellulose

Ph. Eur. : CELLULOSE, MICROCRYSTALLINE

Packaging information

| Grade | Net weight | Packaging type |

|---|---|---|

| UF-702 | 15 kg | Polyethylene bag in kraft paper bag |

| UF-711 | 15 kg | Polyethylene bag in kraft paper bag |

Formulation examples

* You can download PDF files after log in Member page.

Balance of tablet hardness and tablet disintegration - High shear granulation

Ceolus™ UF

In high shear granulation, the granulation time affects the compactibility, disintegration and dissolution properties of granules. In particular, longer granulation time tends to deteriorate the compactibility, disintegration or dissolution properties. Ceolus™ UF grade is a round and porous MCC and its high swellability can reduce adverse effects of high shear granulation on tablet hardness, disintegration and dissolution.

Challenges

Key words

Improvement of API content uniformity

Ceolus™ UF

API segregation is one of typical challenges in direct compression of low dose API formulations. A porous MCC particle forms an ordered mixture by API adhesion on its surface. The ordered mixture mitigates API segregation risk and provides better API content uniformity compared to conventional MCCs.

Challenges

Key words

Improvement of tablet weight variance under high speed tableting

Ceolus™ UF

In direct compression of formulation with poorly flowable APIs, increasing the tableting speed tends to cause tablet weight variance. A high flowable MCC may improve flowability of mixed powder, prevent tablet weight variance, and increase tableting speed.

Challenges

Key words