Ceolus™ KG

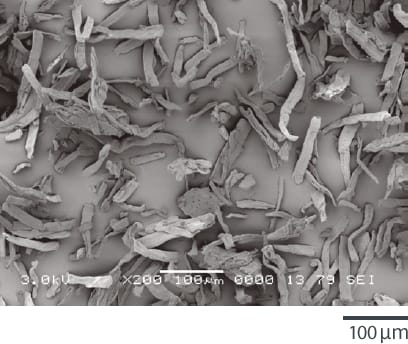

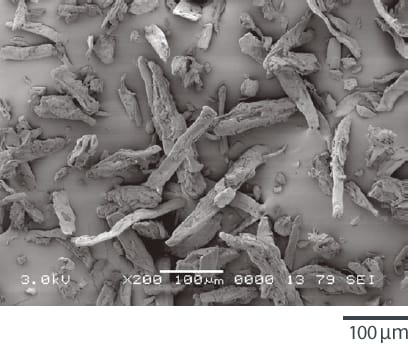

Ceolus™ KG is a highly compactible MCC with fibrous particles.

It enables poorly compactible and/or high dose formulations. It solves tableting issues such as insufficient

hardness, sticking or capping.

Functional benefits

- Enables poorly compactible and/or high dose formulations

- Solves tableting issues

Insufficient hardness, sticking, capping, high friability - Enables unique and patient-friendly dosage forms

MUPS, ODT, multiple-layer tablets, multiple-API-combination tablets, small tablets, mini tablets - Enables low-pressure tableting

Applicable for pressure-sensitive API tablets and coated granules

Function & features

- High compactibility

- High oil absorption

- Fibrous particles

Map of Ceolus™ Compactibility vs. Flowability

* Comparison of tablet hardness, with the formulation of PH-101 = 1 set as the index point

Formulation: Acetaminophen/MCC = 70/30

Experimental

example

Tablet hardness

Tablet friability

* All tablets with PH-102 were broken during the friability test due to inherent capping tendency.

Metformin HCl/MCC/CCS/SiO2/Mg-St=70.8/26.1/2.1/0.5/0.5(%),

Direct compression (Rotary Press), Tablet size: 760 mg,φ12.0 mm - 16 R

Grade lineup

KG-1000

KG-802

Subject of comparison

PH-101

General properties

| Grade | Average Particle Size(μm) |

Bulk density (g/cm3) | Repose Angle(°) | Loss on Drying(%) |

Water absorption (%) |

Oil absorption (%) |

|

|---|---|---|---|---|---|---|---|

| Ceolus™ KG Highly compactible MCC with fibrous particles |

KG-1000 | 50 | 0.12 | 57 | 2.0-6.0 | 290 | 210 |

| KG-802 | 50 | 0.21 | 49 | 2.0-6.0 | 230 | 160 | |

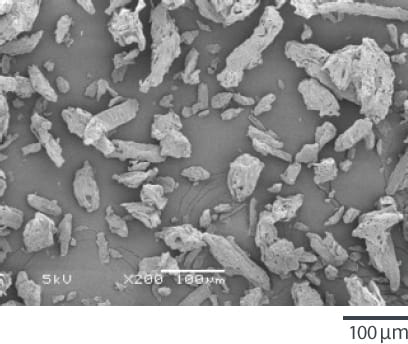

| Ceolus™ PH Standard grade with high quality |

PH-101 | 50 | 0.29 | 45 | 2.0-6.0 | 200 | 120 |

| PH-102 | 90 | 0.30 | 42 | 2.0-6.0 | 200 | 140 |

All values presented here are solely for the purpose of basic reference and should not be regarded as specifications.

Pharmacopoeia listings

JP : Microcrystalline Cellulose

USP/NF : Microcrystalline Cellulose

Ph. Eur. : CELLULOSE, MICROCRYSTALLINE

Packaging information

| Grade | Net weight | Packaging type |

|---|---|---|

| KG-1000 | 10 kg | Polyethylene bag in kraft paper bag |

| KG-802 | 15 kg | Polyethylene bag in kraft paper bag |

Formulation examples

* You can download PDF files after log in Member page.

Capping Prevention - High dose tablets

Ceolus™ KG

Formulations with poorly compactible or high-dose APIs have the higher possibility of capping. Conventional MCC grades have insufficient compactibility, and the inherent capping can result in high tablet friability. By using a highly compactible MCC, the tablet's binding ability is increased and capping can be suppressed.

Challenges

Key words

Improvement of tablet friability - High-dose tablets

Ceolus™ KG

High-dose formulations by direct compression limits space for excipients, and tableting issues such as capping, sticking and tablet friability are predicted. These issues could be solved with a small amount of a highly compactible MCC.

Challenges

Key words

Improvement of tablet friability for film coating

Ceolus™ KG

Regarding tablet film coating, the airborne powder inside the coating machine can penetrate the film layer, potentially affecting tablet dissolution. By using a highly compactible MCC, the tablet's binding ability is increased and tablet friability is reduced, leading to reduced impact on the film layer and tablet dissolution.

Challenges

Key words