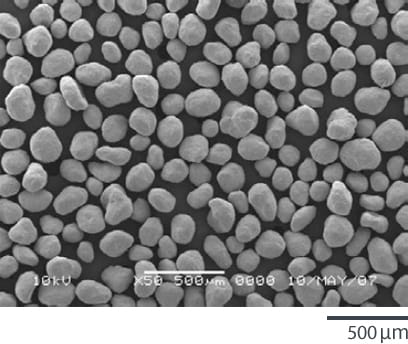

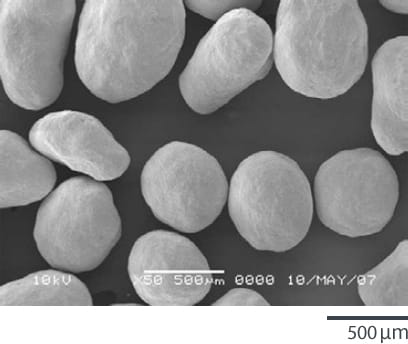

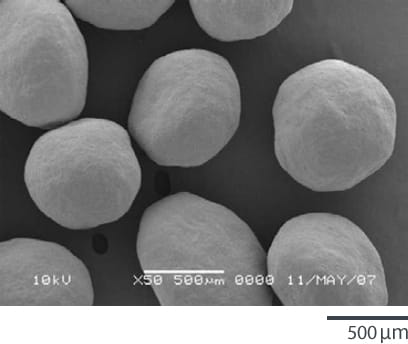

Celphere™

A 100% MCC sphere, Celphere™ facilitates precise dissolution profiles of controlled release formulations by its

high sphericity and narrow particle size distribution.

Functional benefits

- Facilitates precise dissolution profile of controlled release formulation

- Yield improvement

Reduces agglomeration, tolerance with high stress and coating machine varieties

Function & features

- High sphericity

- Narrow particle size distribution

- High mechanical strength

Experimental

example

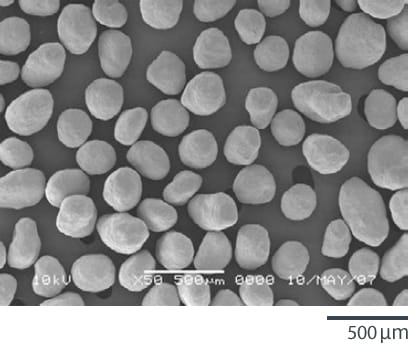

Example 1:

Film coating in aqueous coating system

* Percentage of particles with particle size larger than 500μm

Base granules : Vitamin B2 (2%) layered on Celphere™ or sugar sphere

Film coating : Ethylcellulose aqueous dispersion/Triethyl citrate/HPMC/

Water=10.9/2.7/1.4/85 (up to 10% against base granules)

Equipment : Wurster fluid bed coater

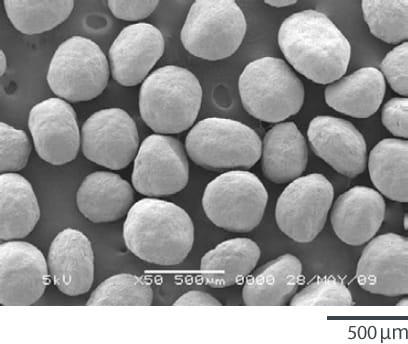

Example 2:

Dissolution profile affected by shear stress

Drug layering : Theophylline/Corn starch/Sucrose=10/10/20 + HPC-L aq. (3 wt%)

Film coating : Ethylcellulose aqueous dispersion/Acetylated monoglycerides/Talc=100/33/57

Equipment : CF-Granulator

Grade lineup

CP-102

CP-203

CP-305

CP-507

CP-708

General properties

| Grade | Particle size range (μm) | Sphericity | Bulk density (g/cm3) | Water absorption (%) |

|---|---|---|---|---|

| CP-102 | 106-212 | 1.2 | 0.83 | 100 |

| CP-203 | 150-300 | 1.1 | 0.87 | 100 |

| CP-305 | 300-500 | 1.1 | 0.97 | 110 |

| CP-507 | 500-710 | 1.2 | 0.97 | 70 |

| CP-708 | 710-850 | 1.2 | 0.93 | 65 |

All values presented here are solely for the purpose of basic reference and should not be regarded as specifications.

Pharmacopoeia listings

JPE : Microcrystalline Cellulose Spheres

USP/NF : Microcrystalline Cellulose

Ph. Eur. : CELLULOSE, MICROCRYSTALLINE

Packaging information

| Net weight | Packaging type |

|---|---|

| 20 kg | Polyethylene bag in carton box |

Formulation examples

* You can download PDF files after log in Member page.

MCC sphere for controlled release formulations

Celphere™

Film coating with MCC spheres causes less agglomeration than with sugar spheres regardless of the film coating conditions such as spray rate because of their moderate water absorption capacity without dissolving. Also, film coating with MCC spheres causes less damage to core particles than with sugar spheres because of their high mechanical strength. These results suggest MCC spheres facilitates precise dissolution profile of controlled release formulations.

Challenges

Key words

MCC sphere for controlled release formulations

Celphere™

In the case of film coating with sugar spheres, core particles dissolve in water and the granules become unstable. It indicates negative impact on dissolution profile would be assumed due to external shear stress such as the gastrointestinal tract. On the other hand, film coated granules with MCC spheres are more robust against external shear stress, and maintain stable dissolution profile because of insoluble property of MCC.

Challenges

Key words

Reduction of agglomeration in coating process

Celphere™

Drug layering with MCC spheres causes less agglomeration than with sugar spheres regardless of the drug layering conditions such as spray rate because of their moderate water absorption capacity without dissolving. This result suggests that the use of MCC sphere improves productivity.

Challenges

Key words